Why is there a cement powder shortage? Concrete is one of the maximum extensively fed-on substances globally (0.33 most effective to water and air), and it is money owed for around 8% of the world’s CO2 emissions. And even though it’s most effective in a small fraction of the concrete mixture, Portland cement contributes 80-90% of concrete’s CO2 emissions. However, numerous options to immediately portland cement available in the marketplace these days lessen concrete’s carbon footprint.

The primary technique for developing greener concrete is CO2 sequestration, which converts CO2 right into a mineral trapped in the concrete completely and gives even more compressive strength. In addition, a new technology reformulates cement with substances that permit producers to apply much less portland. One thrilling up-and-coming generation uses geopolymers as an opportunity to portland cement, substituting it with substances such as fly ash, floor-granulated blast furnace slag, meta-kaolin, floor mineral micro-silica or different non-gypsum primarily based totally minerals to lessen the environmental effect.

DiscontinuedNews is impartial and independent, and every day, we create distinctive, world-class programs, news, and content that inform, educate and entertain millions of people worldwide.

Why There Is Cement powder shortage Worldwide?

Implement Multi-use ProductsUsing merchandise with more than one blessing won’t clear up the cement shortage. However, it may assist mitigate the effect it has on your task timelines and finances by slicing more than one time-ingesting step down to one.

For example, search for flexible answers which include: A remedy and seal that still waterproofs and creates an inner moisture membrane, strengthening concrete even as giving it longevity.A product that bonds to concrete without requiring a brand new moisture-vapor membrane or “vapor retarder” (for trench filling). Fibers might provide greater electricity even by supplying more excellent rectangular yards of concrete.

Since the COVID-19 pandemic, customers and corporations have confronted many shortages. The shortages have ranged from daily-use grocery merchandise to state-of-the-art semiconductors for cars. Some customers have additionally been going through a scarcity of cement and concrete.

There are delivery chain problems withinside the cement industry. The COVID-19 pandemic has been a delivery chain nightmare for many industries, and cement hasn’t been an exception. Like with many different industries, at the same time as the call for cement rebounded, the delivery aspect struggled to hold pace.

According to the PCA (Portland Cement Association), which is a set within the American cement industry, numerous elements hamper cement’s delivery chain within the country. First, the call has been strong, which is mediated through the increase in residential and industrial creation activity.

The PCA additionally indexed manufacturing cutbacks and upkeep delays during the pandemic for disrupting the delivery chain. Adverse climate conditions, low inventories, and exertion shortages introduced pressure on the delivery chain. Like with different goods, a scarcity of drivers approaches that anything cement vegetation produced took longer than standard to attain consumers.

U.S. cement call for is predicted to be sturdy

In its report, the PCA stated that it expects U.S. cement to call for an upward push of 2.7% in 2022, which will gradually rise to 1.1% in 2023. However, the forecast does not encompass any bump from better authorities’ spending on infrastructure due to the fact the invoice surpassed after the report.

It additionally stated that 17 cement flowers withinside the USA are up for hard work negotiation in 2022. Any challenging work problems at those flowers will upload to the call-for-deliver mismatch. Once the infrastructure spending begins to evolve to advantage steam, it’ll boom the call for cement and concrete.

What are the essential cement manufacturers withinside the U.S.?

LafargeHolcim is the most critical cement manufacturer withinside the U.S. In its income name for the fourth zone of 2021, the organization stated that the overall performance of its North America commercial enterprise changed into “outstanding” in 2021. The organization noticed, in particular sturdy calls for withinside the fourth zone. However, LafargeHolcim did not point out the lack of cement or concrete withinside the location, and it wasn’t featured throughout analysts’ questions.

Cemex, Lehigh Hanson, Buzzi Unicem, and Ash Grove Cement are the various essential cement manufacturers within the U.S. Cement is the actual uncooked fabric for generating concrete, and a maximum of the cement reveals its manner into concrete.

How intense is the cement scarcity withinside the U.S.?

While there is not a prime national scarcity of cement, there are wallets in which cement has been briefly delivered. For example, a few contractors in Texas have confronted a cement scarcity.

Things have to get somewhat higher withinside the 2d 1/2 of 2022. As the U.S. financial system cools down after the sturdy increase in 2022, cement calls, particularly correlated to GDP increase, have to taper down. Also, because the hard work pressure availability increases, cement delivery has to get a boost.

One undisputed reason for the lack is a boom in call for. “This is a good-climate summer. And human beings have gotten rid of construction for a while, and the cash has come from governments. The shortages look like chronic thru year-quit at minimum,” Tom Zais, the CEO of BURNCO, informed CBC News.

Cement powder shortage 2022 Canada

That developing call is likewise being exacerbated by a shrinking workforce — which changed into an enterprise problem even earlier than the pandemic started.

“We had been already forecasting that there could be a probable scarcity of workers, more often than not due to the fact the infant boomers make up the sort of considerable share of our workforce,” stated Mary Van Buren, the president of the Canadian Construction Association, explaining that the one’s retirements and the pandemic have devastated the paintings pressure.

Inflation is likewise a factor. Prices for plenty of uncooked creation substances have risen during the last 12 months. Costs for classes like gravel and clay have risen, up 8% according to cents on the remaining summer, in step with Statistics Canada’s uncooked substances charge index. In April 2022, the National Association of Home Builders in the U.S. launched numbers displaying that ready-blend concrete is 9 percent more high-priced than it changed at the beginning of 2021. The affiliation additionally discovered construction fabric charges for objects like lumber, paint, and concrete have risen more significant than 30 according to cent since the reason that begins of the COVID-19 pandemic. Sleiman says that Apex is spending approximately 30 cents more on its concrete than it spent the remaining year.

Concrete shortage Worldwide

Problems with important flora are but another piece of the crisis. In May, one of all B.C.’s most considerable cement flora, the Lafarge facility in Richmond, stuck fire. Production was reduced as a result.

Also in May, a five-week concrete workers’ strike at the Lower Mainland closed down 12 centers operated by 3 companies. One factor impacted 1/2 of creation tasks in Metro Vancouver and the Fraser Valley. That motion concluded at the cease of June.

People inside the enterprise are searching for methods to relieve the pressure. Van Buren said that a longer-time period imaginative and prescient for infrastructure plans throughout the country, permitting professional immigrants to transport to Canada and facilitating college students to be taught in trades, are all methods to transport forward.

In the meantime, Veall says it can simply be a case of waiting for the marketplace to comply with its herbal cycle and calm down.

On the ground, the Ready Mixed Concrete Association of Ontario has a length of “unheard of challenges” to get the resources to supply concrete this year. Toronto-primarily based St Marys Cement introduced at the cease of June that it became briefly postponing income in a maximum of Ontario and couldn’t supply any cement from 3 centers for a whole week due to the issues.

The substance scarcity affecting concrete is anticipated to remain till December at the very least, in step with enterprise forecasts. And that extended uncertainty for the relaxation of the creation season is the main reason for complex selections for groups like Sleiman’s.

When will the concrete shortage end?

In today’s climate-aware international, it’s far an increasing number of not unusual places to surprise approximately the long time viability of something that is based on herbal sources, given how with ease we gobble the one’s sources up and the developing call for the whole lot because of growing populace numbers. Concrete, the second maximum in-call for substance within the international after water, is clearly one such factor of concern.

Will we run out of concrete?

Concrete is a fabric product of many ingredients. We’re correct en route to walking out of the sand for the following couple of hours in lots of international elements, and sand is an essential aspect of concrete. Sand may be manufactured; however, now, no longer in a manner this is as cost-powerful as herbal sand.

Concrete can be the second maximum in-call for substance within the international after water, however, and is the second maximum exploited herbal aid after water, which is far beginning to show. While concrete may be made without sand, it’d be much less economically feasible because of the ready-made nature and simplicity of accessibility that sand presently has.

Supply shortages have affected the development enterprise because the pandemic started approximately years ago. However, now, the difficulty is a scarcity of concrete.

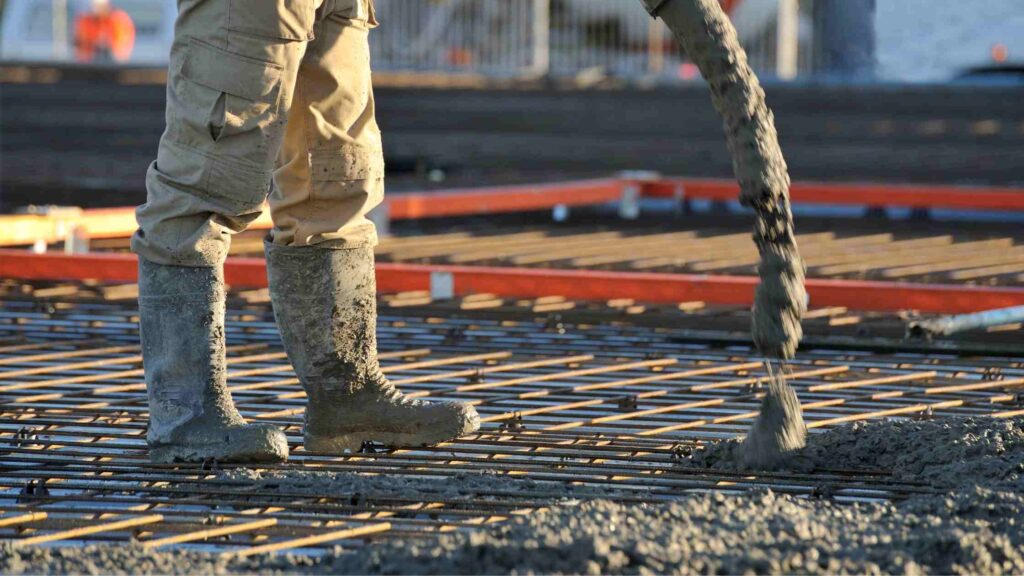

Supply chain troubles and exertion shortages have mainly triggered a loss of one of concrete’s key ingredients: cement mix. Concrete can’t be made without cement mix.

That’s inflicting troubles around northeast Indiana and northwest Ohio, including Huntington county. Huntington county Commissioner Tom Wall says a few tasks across the country are double the cost. Other creation tasks are now delayed, so they’ll lose the country’s time-sensitive investment.

As for homeowners, they’re having a tough time even locating a person to pour concrete for small tasks. The scarcity is inflicting backups for concrete contractors too. They depend upon concrete mixers to make the concrete. But if the mixers don’t have the vital ingredients, they’re restricted in how much concrete they can supply.

The concrete scarcity displays no symptoms and symptoms of letting up every time soon, so one can imply delays for main creation tasks and private domestic enhancements. There has been an extra tough time prevailing as a concrete contractor. With cement in brief, delivery, and the effect of ongoing professional hard work shortages and expanded call for creation initiatives, many are locating themselves on allocation with even their maximum long-term, relied-on concrete suppliers. Scheduled pours are increasingly being paused, moved, returned, and canceled as concrete is rationed, delaying initiatives nationwide.

The good news and difficult instances regularly spur new product improvement and adoption. Many progressive technologies are being created these days that may offset the dependence on portland and lessen mission prices and inefficiencies. Even if attempting new technology changed into cost-prohibitive to your enterprise withinside the past, substances that are to be had now and assist you to figure quicker are probable an extra cost-powerful choice.

What is the Causes of cement shortage?

Architects and the broader creation enterprise were hit with challenging substance shortages in 2021. The delivery chain disaster brought about skyrocketing costs and large lead instances on substances, including timber, and gambling havoc with tasks up and down the country. Government data show that fabric expenses rose monthly between September 2020 and September 2021.

Going into 2022, the shortages appear to be easing, but a few essential merchandises nonetheless stay in quick delivery. In a final replacement week, the Construction Leadership Council (CLC) stated it seemed the Omicron Covid variation had best inflicted ‘limited’ disruption; however, that costs remained a concern, with more than one increase expected.

The architectural career remains being hit by way of means of shortages. The RIBA’s maximum current Future Trends record famous price inflation, twinned with shortages of each substance and people, is inflicting assignment delays and making tendering increasingly tricky.

Our explainer takes inventory of the modern-day records at the delivery chain and affords records on which substances are dealing with fee rises or shortages heading into 2022.

Several factors. The enterprise has now no longer recovered from the devastating effect of the primary wave of the Covid-19 pandemic. At its peak, cloth manufacturing slowed. However, call for elevated housing as house owners launched into development tasks all through lockdown, piling even extra strain on delivery chains.

There is likewise, nonetheless, a whole lot of uncertainty around Brexit. New policies and behind-schedule shipments suggest substances from distant places are more difficult to return back by. Labor shortages have additionally performed a part, which includes the absence of HGV drivers and a shortage of production workers.